Meanwhile, PQR is often a doc that checks if the conventional is being followed by inspecting and answering the document with regards to distinct parts and assessments.

”twelve Each of such ideas, on the other hand, faces two complications. The 1st is realistic — ways to combination widely varying specific Choices so that they lead to meaningful definitions of quality at the marketplace stage. The next is more essential — how to tell apart These product characteristics that connote quality from those that merely increase purchaser pleasure.

If much more than fifteen batches made throughout the review period, Get ready graphical presentation of analytical pattern facts of in-process and finished product.

If the price of obtaining these gains is outweighed because of the increases in contribution obtained by the organization, increased income will final result.68

Validation of this kind of procedures needs to be based on historic knowledge. The measures associated involve the preparation of a specific protocol plus the reporting of the results of the info review, resulting in a conclusion as well as a recommendation.

The expanded review essential through the EU PQR may well not automatically call for added time and methods, in comparison While using the FDA PAR review, because the EU PQR allows for the grouping of products with each other in a single review whereas the FDA does not. If a corporation decides to perform 1 PAR/PQR to fulfill both of those FDA and the EU, then, they would want extra means to carry out an expanded review, for every product.

Other rolls of newsprint, on the other hand, created no shopper issues Despite the fact that they didn't satisfy the standard.23 A number one U.S. company of place air conditioners confronted the other difficulty. Its products have been properly been given by shoppers and really rated by Shopper Reviews. Reject, scrap, and warranty expenses ended up so high, having said that, that enormous losses had been incurred. When the product’s style and design matched consumers’ requires, the failure to observe by means of with restricted conformance in producing Expense the organization dearly.

Just about every of those techniques is focused on the identical stop: cost reduction. Based on the producing-centered strategy, enhancements in quality (that are such as reductions in the number of deviations) produce decreased prices, for blocking defects is considered as less costly than restoring or here reworking them.

A PQR examination report is really a document which contains the outcome of a welding process qualification checks. The purpose of this exam is To guage the suitability of the welding method (pWPS) for use in production.

FDA revised its GMP in January 1995 to remove the prerequisite to the review of all batches developed during the past 12 months also to enable the review of the consultant quantity of batches. The preamble to the revised GMP restrictions states, having said that, that the review of all batches would be ideal once the review of a agent quantity of batches identifies an adverse development. The EU and Q7A PQRs usually do not point out that all batches has to be reviewed, in addition to turned down batches, but these two paperwork also will not exclusively allow for for that review of representative batches.

Quality Administration What exactly are The real key quality assurance and quality Command roles in pharmaceutical producing?

This instance indicates the importance of thoroughly targeting a person’s quality market. The selection of the defensible specialized niche, however, is barely a first step. Operational demands will have to also be fulfilled, for each dimension of quality imposes its have needs within the company. Large performance calls for mindful consideration to structure and a powerful style and design staff; exceptional toughness involves using lengthy-lived or “derated” elements and close cooperation among the engineering and acquiring departments; excellent conformance requires attention to written technical specs and precision click here in assembly; and exceptional serviceability requires a powerful customer service Office and Energetic discipline Reps.

Constant Improvement: APQR fosters a culture of steady improvement by pinpointing spots for enhancement in production procedures, quality Handle programs, and product structure. This brings about optimized operations and elevated performance.

The relationship involving quality and sector share is probably going to rely upon how quality is outlined. If a higher-quality product is one particular with top-quality performance or a large number of features, it is going to commonly be costlier, and can offer in more compact volumes.

Jake Lloyd Then & Now!

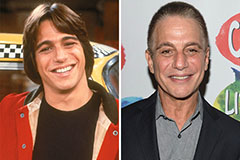

Jake Lloyd Then & Now! Tony Danza Then & Now!

Tony Danza Then & Now! Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now!